Product

Product Details

1.Overview

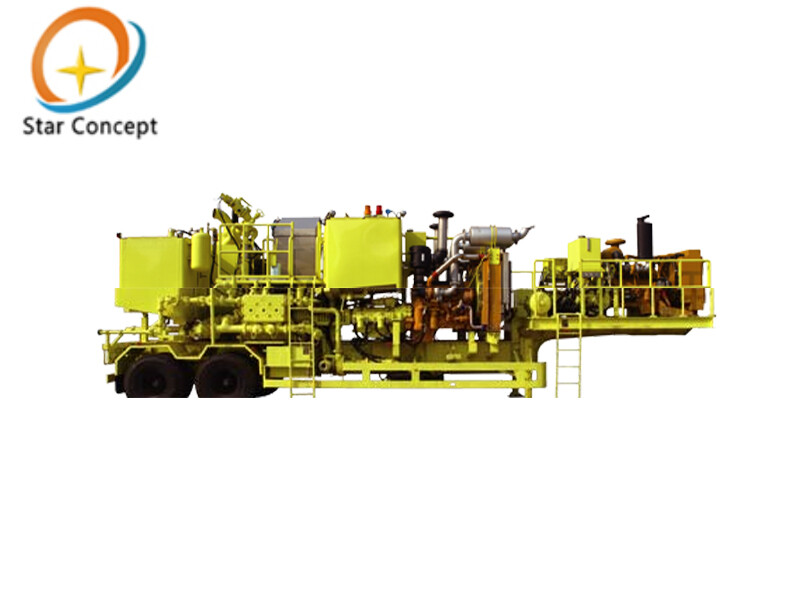

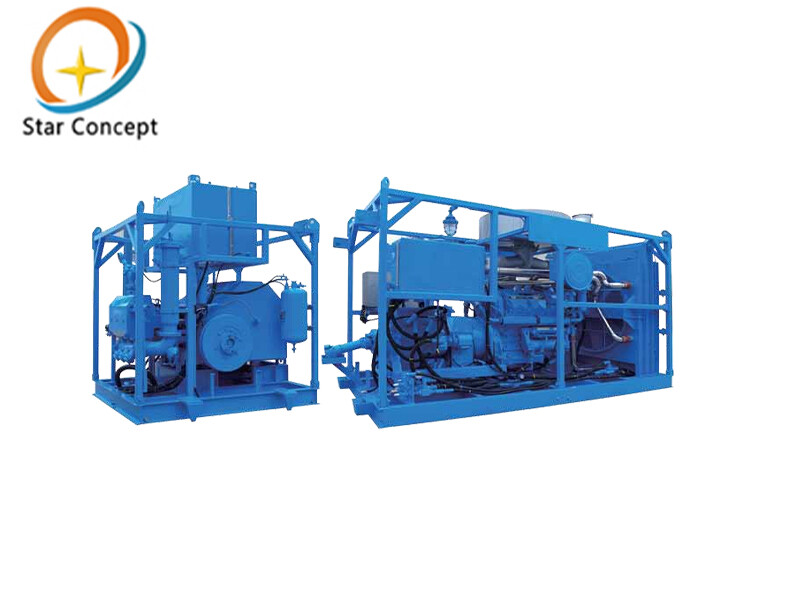

PCTLR-621A double pump cementing trailer is a trailer mounted complete mixing and pump unit equipped with TPH400 plunger pump.

The entire truck is mainly composed of chassis, two engines, two TPB600 triplex pumps, C7 power unit, air system and ACM-III.1auto mixing system.

The whole unit is mainly composed of semi-trailer chassis, two main engines, two transmissions, two TPB600 triplex pumps, C7 power unit with hydraulic system and ACM-IV.1 auto mixing system.

This unit is mainly utilized in cementing job, acidizing job, oil well pressure testing, and other fluid pumping iob, applicable for cementing job in oilfield on land.in gobi desert and remote areas.

2.General specification

Max. working pressure:105MPa (w/ 3" fluid end)

Max. flow: 4.2m3/min (w/two 4 1/2" fluid ends)

Density range: 1.3~2.5g/cm3

Auto control precision: ±0.02 g/cm3

Mixing capacity: 0.3~2.3m3/min

Working ambient temperature:-20°C~50°C

Overall dimension (mm):11240(L) x 2500(W)x4000 (H)

Net weight:27500kg

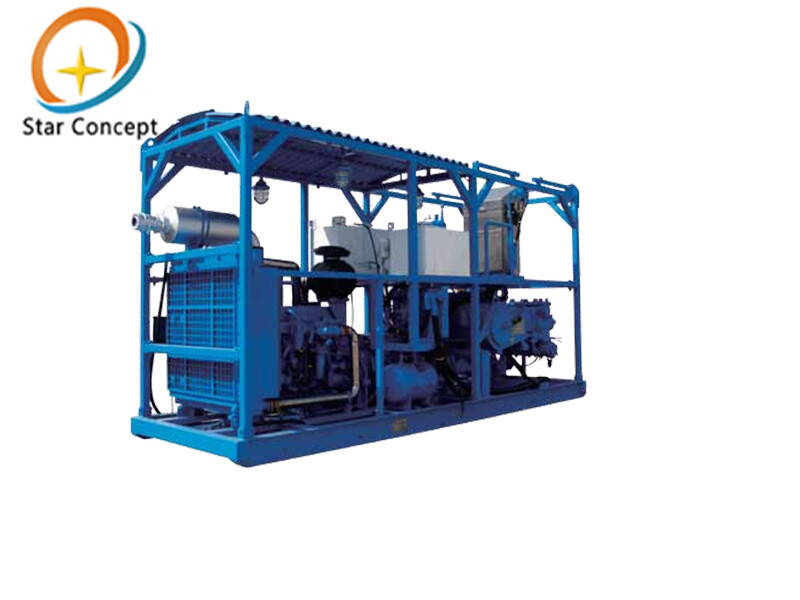

3.Features

Domestic or imported trailer chassis, Low deck, Heavy duty, high temperature, desert type trailer chassis are available.

1m3 surge tank avalible, utilzed to make bulk delivery more stable so as to improve the accuracy of auto control system and sury qualty

Auxiliary C7 Power unit.

High energy recirculating jet mixing system.

Off-center dry cement valve avoids bulk from choking.

Emergency kill system of air inlet shutoff.

Plunger pump overpressure protection system.

SPS non-leakage packing system.

Plunger pump overoressure protection system, engine goes idle automatically, transmission is in neutral position.

F300 Non-radioactive densitometer is easy to wash, safe and relable.

Simplify operation, adapt to working habits in oilfield.

10" operation screen, convenient to monitor the working data.

Portable wireless/ wired data acquisition system.

Related Suggestion

Online Consultation

Dongying Star Concept Petroleum Equipment Co.,Ltd

20 years experiences drilling&cementing equipment manufacturer and exporter