Product

Product Details

Overview

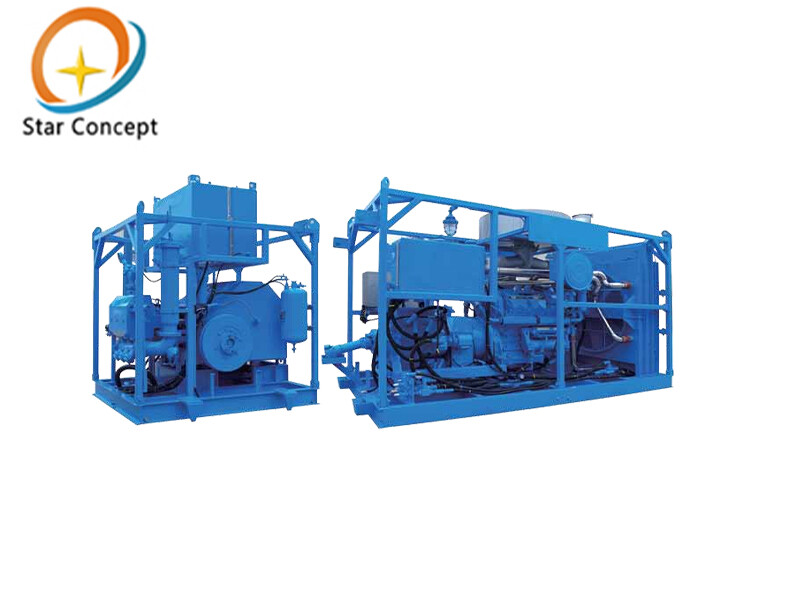

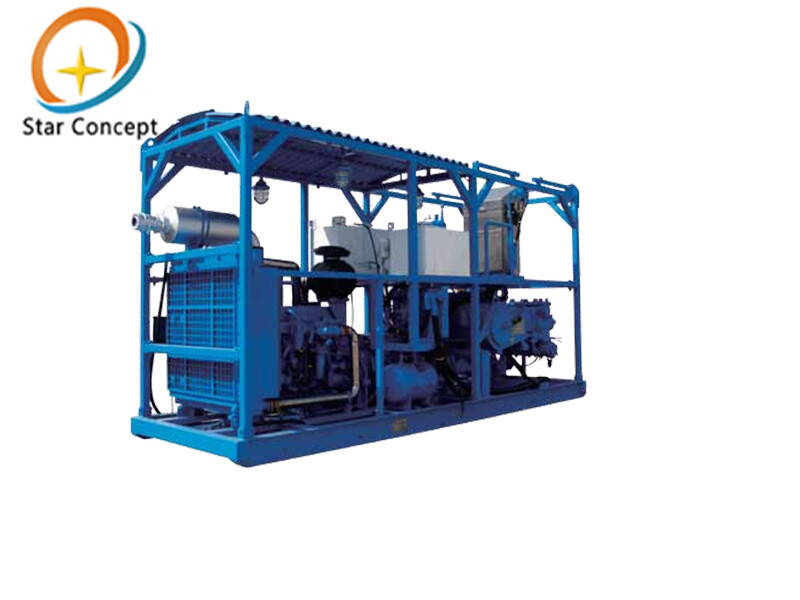

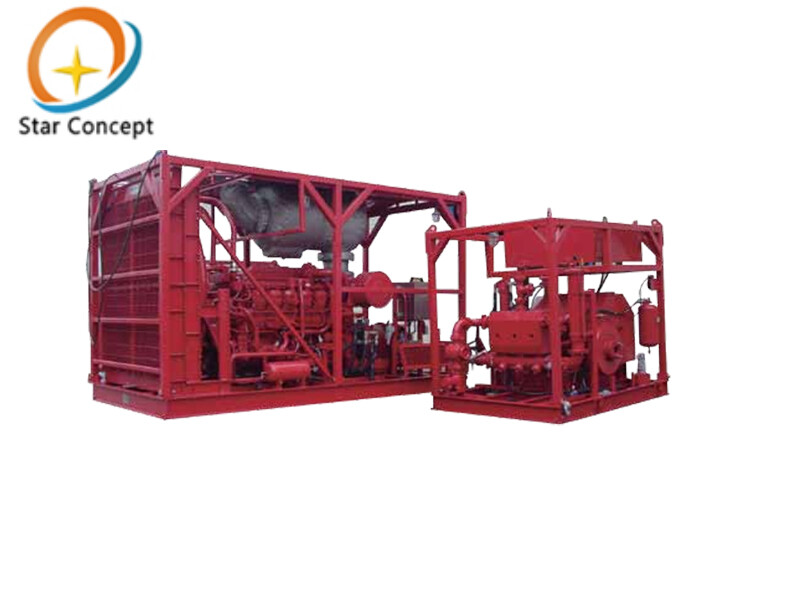

The blending skid is specially developed to mix the fracturing fuid, proppant and various additves according to the preset proporton, and to convey the mixed fuids under certain pressure to the fracturing pump skid. The blending skid consists of the following components and systems: skid frame, engine, transmission case, mixing/agitatng system, screw type sand conveyer, hydraulic system, suction and discharge manifolds, electric circuit and control system.

Primary Technical specification

BGS-20 Blender

Maximum sand fluid displacement: 20 BBL/min (3.2 m³/min)

Maximum discharging pressure: 100 PSI (0.7 Mpa)

Maximum concentration of sand-laden fuid: 10 ppg (1200 kg/m³)

Maximum sand conveying capability: 1,900 pounds/min (862 kg/min)

Volume of blending tank: 1.2 m³

Weight: <9t

Overall dimension (not including the sand storage tank): 5800(L) × 2400 (W) × 2800 (H)

BGS-35 Blender

Maximum displacement of the sand fuid: 35 BBL/min (5.6 m³/min)

Maximum discharge pressure: 100 PSI (0.7 MPa)

Maximum concentraton of the sand fuid: 8.3 ppg (1000 kg/m³)

Maximum sand auger working capability: 10,000 pounds/min (4535 kg/min)

Displacement of dry powder additves:

1# displacement: 0.1~1 (L/min)

2# displacement: 0.5~5 (L/min)

Displacement of liquid additves:

1# pump displacement: 3~25 (L/min)

2# pump displacement: 20~150 (L/min)

Sand tank volume: 1.2 m³

Individual skid weight: <15t

Overall dimension (not including the sand storage tank): 8100(L) × 2400 (W) × 3100 (H)

BGS-50 Blender

Maximum displacement of the sand fuid: 50 BBL/min(8.0 m³/min)

Maximum discharge pressure: 100 PSI (0.7 Mpa)

Maximum concentraton of the sand fuid: 8.3 ppg(1000 kg/m³)

Maximum sand auger working capability: 10,000 pounds/min(4535 kg/min)

Displacement of dry powder additves:

1# displacement: 0.1~1 (L/min)

2# displacement: 0.5~5 (L/min)

Displacement of liquid additves:

1# pump displacement: 3~25 (L/min)

2# pump displacement: 20~150 (L/min)

Sand tank volume: 1.2 m³

Individual skid weight: <15t

Overall dimension (not including the sand storage tank): 8100(L) × 2400 (W) × 3100 (H)

Standard Configuration

BGS-20 Blender

Engine: CAT C7 300 BHP/2200 RPM

Sucton centrifugal pump: MISSION 5” ×4” × 14”

Maximum displacement of the suction centrifugal pump: 3.8 m³/min (water)

Maximum discharging pressure: 70 PSI (0.5 MPa)

Rated rotary speed of the suction centrifugal pump: 1750 RPM

Discharge pump model: MISSION 6” ×5” × 14”

Maximum displacement of the discharge pump: 6.8 m³/min (water)

Maximum discharge pressure:100 PSI (0.7 Mpa)

Rated rotary speed of discharge pump: 1750 RPM

8” sand auger

BGS-35 Blender

Engine: CAT C13 520 BHP/2100 RPM

Suction centrifugal pump: MISSION 8” ×6” × 14”

Maximum displacement of sucton pump: 8.0 m³/min (water)

Maximum discharge pressure: 70 PSI (0.5 MPa)

Sucton pump rotary speed: 1750 RPM

Discharge pump model: MISSION 8” × 6”× 14”

Maximum displacement of discharge pump: 9.5 m³/min (water)

Maximum discharge pressure:100 PSI (0.7 MPa)

Rated rotary speed of discharge pump: 1750 RPM

2 ea 8” sand augers

BGS-50 Blender

Engine: CAT C13 520 BHP/2100 RPM

Sucton centrifugal pump: MISSION 8” × 6” ×14”

Maximum displacement of suction pump: 8.0 m³/min (water)

Maximum discharge pressure: 70 PSI (0.5 MPa)

Rated rotary speed of sucton pump: 1750 RPM

Discharge pump model: MISSION 10” × 8” × 14”

Maximum displacement of discharge pump: 12 m³/min (water)

Maximum discharge pressure:100 PSI (0.7 MPa)

Rated rotary speed of discharge pump: 1750 RPM

2 ea 12” sand augers

Features

It is mainly developed for ofshore sand control fracturing service. It is used to accurately mix and convey the sand-laden fuid.

2. The blending skid is of split-structure and the individual weight is controlled within 9 tons, which is convenient for hoistng.

3. The design ensures the quick switch and interchange of the suction and discharge pipe systems, which helps realize the double suctions and double discharges and brings the convenience of the equipment arrangement. It is achieved by controlling the isolating valve.

4. The blending skid is controlled by the hydraulic driven electric control system. It has two control modes, the auto control mode and the manual control mode, which can be quick switched when it is required.

5. The sand auger may be either place in the middle or at the rear of the skid for the easy and contnuous feeding sand.

6. The blending skid may be collocated with diferent kinds of additves systems which have various sizes or brands of additves.

7. The blending skid introduces SJS ABCS blender auto control system, which ensures the achievement of auto control over the sand fluid concentration, the sand auger rotating speed, the feeding speed of the additives and the level of the sand fluid.

Related Suggestion

Online Consultation

Dongying Star Concept Petroleum Equipment Co.,Ltd

20 years experiences drilling&cementing equipment manufacturer and exporter