Product

Product Details

1.Overview

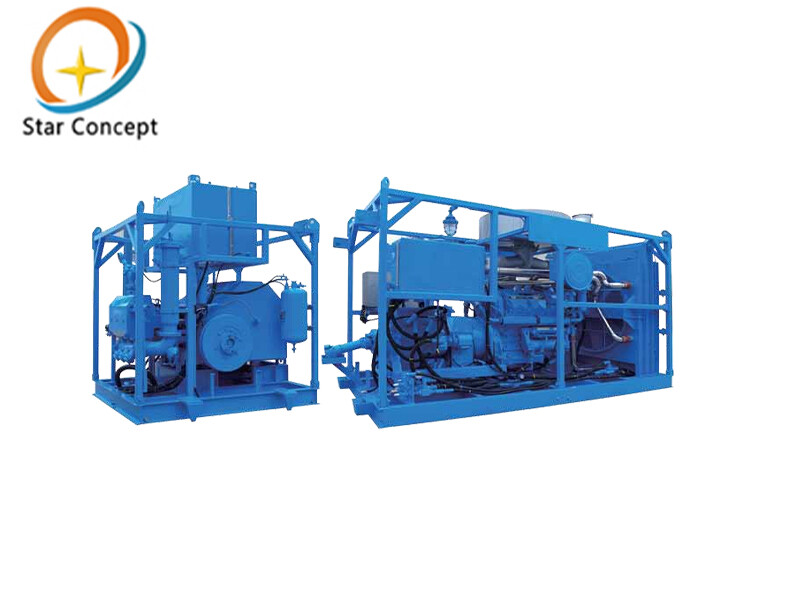

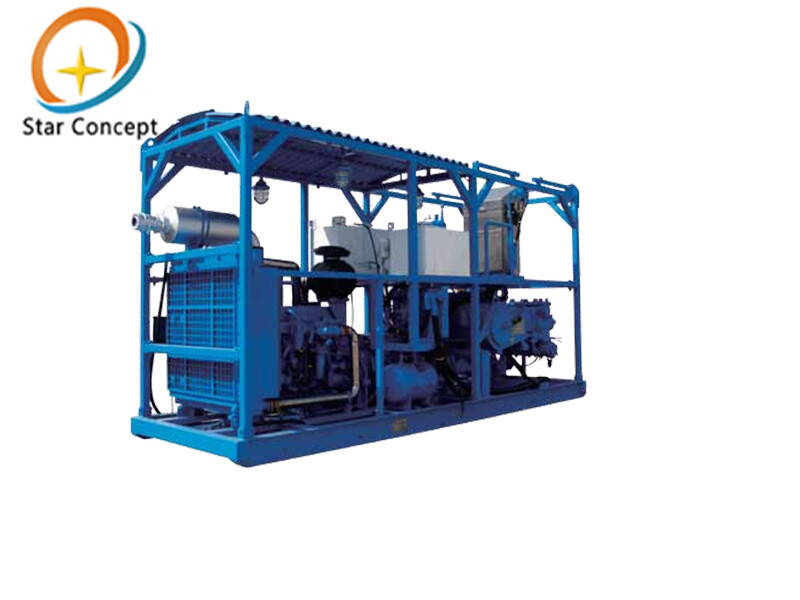

PCT-621A double pump cementing truck adopts TPB600 pump with the features of compact structure and light weight, with standard confiquration of VOLVO FM440 6X6 chassis.

SERVA TPB600 pump has prominent features of small volume and light weioht. With two pump back to back instalation, the overall width will only be 2580mm which can extremely decrease the overall dimension (weight) of unit, especially applicable to truck-mounted units or offshore equipments.

2.General specification

Max. working pressure:

Max. pressure: 69 MPa(w/ 3 1/2" fluid end)

Max. pressure 97.5 MPa (w/ 3" fluid end)

Max. flow: 3.0 m3/min(w/ one 3" and one 4 1/2" Fluid End)

3.4 m3/min(w/ two 3 1/2" and one 4 1/2"Fluid Ends)

Density range: 1.3-2.5g/cm3

Auto control precision: ±0.02 g/cm3

Mixing capacity: 0.3-2.3m3/min

Working ambient temperature:-20°c~50°C

Overall dimension (mm):11450(L)x 2600(W) x 4200 (H)

Net weight: 30000kg

3.Features

1m³ surge tank avalible, utilized to make bulk delivery more stable so as to improve the accuracy of auto control system and slurry quality.

The mixing power is partially supplied by chassis which increases the actual operation power of main engine.

High energy recirculating jet mixing system.

Off-center dry cement valve avoids bulk from choking

Emergency kill system of air inlet shutoff.

SPS non-leakage packing system.

Plunger pump overpressure protection system.

F300 Non-radioactive densitometer is easy to wash, safe and reliable.

Simplify operation, adapt to working habits in oilfield.

10"operation screen, convenient to monitor the working data.

Portable wireless/ wired data acquisition system.

Diesel fired coolant pre-heat system available. The heater allows the engine to be preheated before starting without the use of external power.

Related Suggestion

Online Consultation

Dongying Star Concept Petroleum Equipment Co.,Ltd

20 years experiences drilling&cementing equipment manufacturer and exporter